Oven - Electric

Machinelist: Oven - Electric

Oven - Electric

- IproMac e.K.

- Ennertsweg 38 b

- 58675 Hemer

- Deutschland

-

+49 (0) 170 27 32 014

-

w.schneegass@ipromac.de

www.ipromac.de

#2075-9003 · Oven - Electric

LAC - Schmelzofen PTS 970/12 - - 2023 -

Technical details

NEW GOODS with manufacturer guarantee ORIGINAL PACKAGED Melting electric tilting furnace PTS 970 /12 Technical parameters Mark: PTS 970/12 Max. temperature: 1200 °C Recommended range of operating temperatures: 650-1000 °C (in crucible) Capacity: 840 kg of Al Crucible type Noltina or equivalent: TBNS 800 Capacity of crucible: 320 l External dimensions (w x h x d): 2250 x 2450 x 2000 mm Melting output**: 250 kg of Al alloys/h Heating power input: 102 kW Weight: 3500 kg Protection*: 200/3 Voltage: 3/N/PE 400/230 V AC 50 Hz *Protection can vary depending on the accessories chosen (at additional cost). **The melting output values specified in the table are the maximum values. They are achievable if the conditions mentionedbelow are complied with. Approximately 80 % of the maximum value of the melting output is achieved during actualoperation. Description The furnace is used as a melting device with the possibility of tilting and pouring the melt into the transport pan or transport holding furnace for subsequent processing at temperatures up to 1200 °C (in the furnace chamber, approximately 1100 °C in a crucible – these values are guaranteed only when using unworn Noltina crucible of the appropriate size). Standard design of furnace •Crucible •Hydraulic furnace tilting •Ht40T controller •Limit unit •Protective collar of crucible •Manual lid •Emergency drain at the bottom of the furnace, with flap •“S” type limiting and controlling thermocouple •3 ammeters for checking the status of the heating elements •Switching of the heaters using contactors •Residual current protector •Legs to facilitate handling by a forklift at volumes of 400 l or more •Connection between the furnace and switchboard, within a metal hose with a plasticprotector, length of up to 5 m •Wall switchboard •Hydraulic aggregate is on the right side of the furnace, the hand lever control is on the rightside of the furnace Benefits: • Furnace chamber with a long-term service life, mechanical durability and resistance to corrosion • Simple replacement of the spirals if they become damaged • Simple replacement of the crucible by dismounting the top furnace cover • Use of the lid reduces operational costs • Robust, durable design for heavy-duty operations • The chamber is provided with an emergency drain with an insulated flap so that it is protected against damage in the event of melt leakage from the crucible • Easy to install, easy to control • Custom adjustments • 24-month warranty • Mechanical durability • High melting output

- IproMac e.K.

- Ennertsweg 38 b

- 58675 Hemer

- Deutschland

-

+49 (0) 170 27 32 014

-

w.schneegass@ipromac.de

www.ipromac.de

#2075-9004 · Oven - Electric

LAC - Schmelzofen PTS 970/12 - - 2023 -

Technical details

NEW GOODS with manufacturer guarantee ORIGINAL PACKAGED Melting electric tilting furnace PTS 970 /12 Technical parameters Mark: PTS 970/12 Max. temperature: 1200 °C Recommended range of operating temperatures: 650-1000 °C (in crucible) Capacity: 840 kg of Al Crucible type Noltina or equivalent: TBNS 800 Capacity of crucible: 320 l External dimensions (w x h x d): 2250 x 2450 x 2000 mm Melting output**: 250 kg of Al alloys/h Heating power input: 102 kW Weight: 3500 kg Protection*: 200/3 Voltage: 3/N/PE 400/230 V AC 50 Hz *Protection can vary depending on the accessories chosen (at additional cost). **The melting output values specified in the table are the maximum values. They are achievable if the conditions mentionedbelow are complied with. Approximately 80 % of the maximum value of the melting output is achieved during actualoperation. Description The furnace is used as a melting device with the possibility of tilting and pouring the melt into the transport pan or transport holding furnace for subsequent processing at temperatures up to 1200 °C (in the furnace chamber, approximately 1100 °C in a crucible – these values are guaranteed only when using unworn Noltina crucible of the appropriate size). Standard design of furnace •Crucible •Hydraulic furnace tilting •Ht40T controller •Limit unit •Protective collar of crucible •Manual lid •Emergency drain at the bottom of the furnace, with flap •“S” type limiting and controlling thermocouple •3 ammeters for checking the status of the heating elements •Switching of the heaters using contactors •Residual current protector •Legs to facilitate handling by a forklift at volumes of 400 l or more •Connection between the furnace and switchboard, within a metal hose with a plasticprotector, length of up to 5 m •Wall switchboard •Hydraulic aggregate is on the right side of the furnace, the hand lever control is on the rightside of the furnace Benefits: • Furnace chamber with a long-term service life, mechanical durability and resistance to corrosion • Simple replacement of the spirals if they become damaged • Simple replacement of the crucible by dismounting the top furnace cover • Use of the lid reduces operational costs • Robust, durable design for heavy-duty operations • The chamber is provided with an emergency drain with an insulated flap so that it is protected against damage in the event of melt leakage from the crucible • Easy to install, easy to control • Custom adjustments • 24-month warranty • Mechanical durability • High melting output

- IproMac e.K.

- Ennertsweg 38 b

- 58675 Hemer

- Deutschland

-

+49 (0) 170 27 32 014

-

w.schneegass@ipromac.de

www.ipromac.de

#2075-9005 · Oven - Electric

LAC - Schmelzofen PTS 970/12 - - 2023 -

Technical details

NEW GOODS with manufacturer guarantee ORIGINAL PACKAGED Melting electric tilting furnace PTS 970 /12 Technical parameters Mark: PTS 970/12 Max. temperature: 1200 °C Recommended range of operating temperatures: 650-1000 °C (in crucible) Capacity: 840 kg of Al Crucible type Noltina or equivalent: TBNS 800 Capacity of crucible: 320 l External dimensions (w x h x d): 2250 x 2450 x 2000 mm Melting output**: 250 kg of Al alloys/h Heating power input: 102 kW Weight: 3500 kg Protection*: 200/3 Voltage: 3/N/PE 400/230 V AC 50 Hz *Protection can vary depending on the accessories chosen (at additional cost). **The melting output values specified in the table are the maximum values. They are achievable if the conditions mentionedbelow are complied with. Approximately 80 % of the maximum value of the melting output is achieved during actualoperation. Description The furnace is used as a melting device with the possibility of tilting and pouring the melt into the transport pan or transport holding furnace for subsequent processing at temperatures up to 1200 °C (in the furnace chamber, approximately 1100 °C in a crucible – these values are guaranteed only when using unworn Noltina crucible of the appropriate size). Standard design of furnace •Crucible •Hydraulic furnace tilting •Ht40T controller •Limit unit •Protective collar of crucible •Manual lid •Emergency drain at the bottom of the furnace, with flap •“S” type limiting and controlling thermocouple •3 ammeters for checking the status of the heating elements •Switching of the heaters using contactors •Residual current protector •Legs to facilitate handling by a forklift at volumes of 400 l or more •Connection between the furnace and switchboard, within a metal hose with a plasticprotector, length of up to 5 m •Wall switchboard •Hydraulic aggregate is on the right side of the furnace, the hand lever control is on the rightside of the furnace Benefits: • Furnace chamber with a long-term service life, mechanical durability and resistance to corrosion • Simple replacement of the spirals if they become damaged • Simple replacement of the crucible by dismounting the top furnace cover • Use of the lid reduces operational costs • Robust, durable design for heavy-duty operations • The chamber is provided with an emergency drain with an insulated flap so that it is protected against damage in the event of melt leakage from the crucible • Easy to install, easy to control • Custom adjustments • 24-month warranty • Mechanical durability • High melting output

- IproMac e.K.

- Ennertsweg 38 b

- 58675 Hemer

- Deutschland

-

+49 (0) 170 27 32 014

-

w.schneegass@ipromac.de

www.ipromac.de

#2075-9006 · Oven - Electric

LAC - Schmelzofen PTS 970/12 - - 2023 -

Technical details

NEW GOODS with manufacturer guarantee ORIGINAL PACKAGED Melting electric tilting furnace PTS 970 /12 Technical parameters Mark: PTS 970/12 Max. temperature: 1200 °C Recommended range of operating temperatures: 650-1000 °C (in crucible) Capacity: 840 kg of Al Crucible type Noltina or equivalent: TBNS 800 Capacity of crucible: 320 l External dimensions (w x h x d): 2250 x 2450 x 2000 mm Melting output**: 250 kg of Al alloys/h Heating power input: 102 kW Weight: 3500 kg Protection*: 200/3 Voltage: 3/N/PE 400/230 V AC 50 Hz *Protection can vary depending on the accessories chosen (at additional cost). **The melting output values specified in the table are the maximum values. They are achievable if the conditions mentionedbelow are complied with. Approximately 80 % of the maximum value of the melting output is achieved during actualoperation. Description The furnace is used as a melting device with the possibility of tilting and pouring the melt into the transport pan or transport holding furnace for subsequent processing at temperatures up to 1200 °C (in the furnace chamber, approximately 1100 °C in a crucible – these values are guaranteed only when using unworn Noltina crucible of the appropriate size). Standard design of furnace •Crucible •Hydraulic furnace tilting •Ht40T controller •Limit unit •Protective collar of crucible •Manual lid •Emergency drain at the bottom of the furnace, with flap •“S” type limiting and controlling thermocouple •3 ammeters for checking the status of the heating elements •Switching of the heaters using contactors •Residual current protector •Legs to facilitate handling by a forklift at volumes of 400 l or more •Connection between the furnace and switchboard, within a metal hose with a plasticprotector, length of up to 5 m •Wall switchboard •Hydraulic aggregate is on the right side of the furnace, the hand lever control is on the rightside of the furnace Benefits: • Furnace chamber with a long-term service life, mechanical durability and resistance to corrosion • Simple replacement of the spirals if they become damaged • Simple replacement of the crucible by dismounting the top furnace cover • Use of the lid reduces operational costs • Robust, durable design for heavy-duty operations • The chamber is provided with an emergency drain with an insulated flap so that it is protected against damage in the event of melt leakage from the crucible • Easy to install, easy to control • Custom adjustments • 24-month warranty • Mechanical durability • High melting output

- IVW GMBH

- Niederrheinstr.298

- 40489 Düsseldorf

- Deutschland

-

(0049)211-4184428

(0049)211-4184430 -

cd@ivwgmbh.com

www.ivwgmbh.com

#1088-E00969 · Oven - Electric

SAFED - Bandofen - - 2000 - Siemens

Technical details

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-M863 · Oven - Electric

Westeneng - 150 - - 1998 -

Technical details

Brand Westeneng Type 150 Year of make 1998 Workpiece length 3.000 mm Table width 340 mm Content 295.80 L Engine power 12 kW Machine size (lxwxh) 3.450 x 640 x 1.630 mm

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

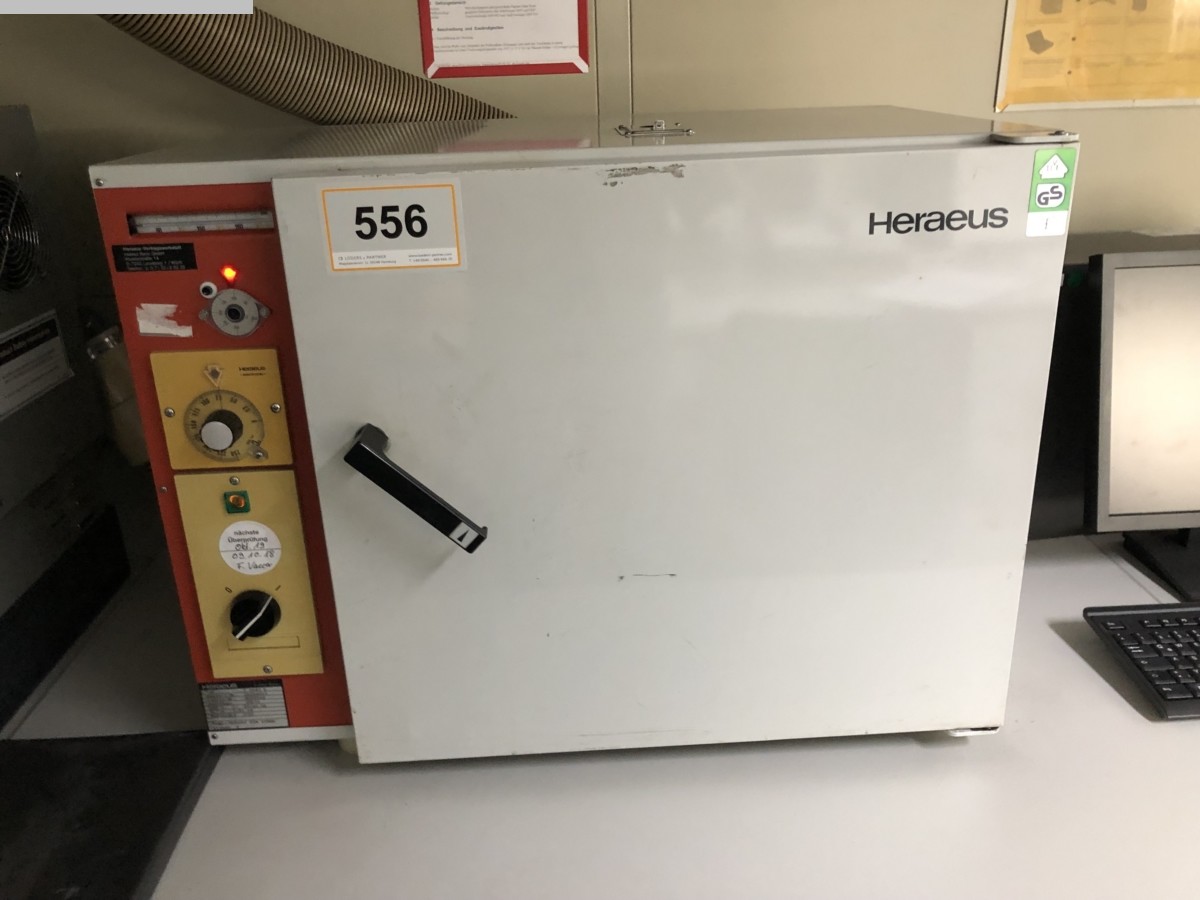

#1049-769705 · Oven - Electric

HERAEUS - RL320E - - 1985 -

Technical details

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-739175 · Oven - Electric

NOLZEN - WT 20/19/40 - - 1982 -

Technical details

- MW-MACHINES

- Dorf 9

- 4133 Hofkirchen

- Österreich

-

+43 (0)66718068977

- -

info@machines-mw.at

machines-mw.at

#2077-90025 · Oven - Electric

AICHELIN - WDE Gr. 40/25/60 - - 1977 -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de